SME transformation: why ever more companies turn to robotics and automation

April 29, 2025

- Digital solutions simplify cobot risk evaluation

- Decreasing price levels make robotics attractive for SMEs

- Robotics application scenarios from canteen kitchens to manufacturing

What if work no longer felt like work? And monotonous tasks became entertaining? Or hard labor was replaced by voice commands? automatica 2025 will show how close reality has already come to this vision. Here, exhibitors from all over the world will show how robots, cobots, and humanoids interact with and support humans as new exciting job descriptions are created.

Cobots are gaining ground in the world of work. They assist in rehab therapy, perform monotonous administration tasks, or work in canteen kitchens. For example, automatica exhibitor Fanuc will present a cooking station where a cobot makes sandwiches and a six-axis industrial robot prepares meals. And Yaskawa will demonstrate smart gastronomy solutions with the potential to compensate for the lack of staff.

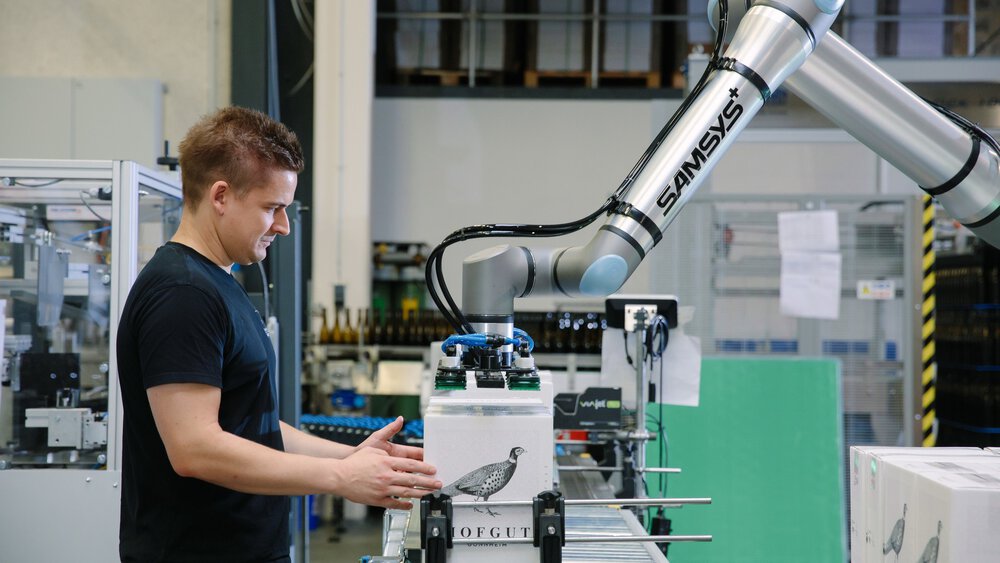

Low-cost automation at Bender+Wirth: a model for SME success

Bender+Wirth is a practical implementation example for cost-efficient automation. The mid-sized company was looking for a solution for CoB (Chip-on-Board) component assembly, but conventional system integrators didn’t fit the budget. They implemented their automation in-house with their own robot cell design based on Scara robots supplied by Epson. Managing Director Martin Bender comments: “The ease of integration and programming was the decisive factor—our employee was fully capable of setting up the system after attending training at Epson.” This example shows that even comparatively small companies with limited resources can benefit from modern robotics.

Digital cobot risk evaluation

In addition, a new patented system developed by Fraunhofer IFF facilitates the risk assessment for cobot deployments, which is required by law. “At automatica, we will present a patented system that makes this risk assessment significantly easier,” says Dr.-Ing. Roland Behrens, Human-Centered Systems Department Manager at Fraunhofer IFF in Magdeburg. “This is particularly beneficial for small and medium-sized companies requiring greater levels of automation but lacking the financial resources to hire a conventional system integrator. This solution enables users to independently carry out risk assessments without any prior knowledge.”

This development could be another boost to cobot deployments as many companies are indeed focusing on the acquisition of robots to compensate for the shortage of skilled workers. And since cobots are becoming increasingly affordable while programming and parameterization become easier, robot deployments are now economical for small companies, too. At automatica, igus will prove just how cost-effective the adoption of robotics can be. This Cologne-based company offers cobots starting at EUR 5,000 and uses its own production facility to demonstrate associated use cases. Alexander Mühlens, Head of Low Cost Automation Business Unit: “For example, we use robots in our injection molding plant to remove sprues. The robot costs around EUR 10,000 and return on investment is achieved after just six months.” This makes cobots an efficient solution for SMEs, particularly since commissioning does not require any robot specialists.

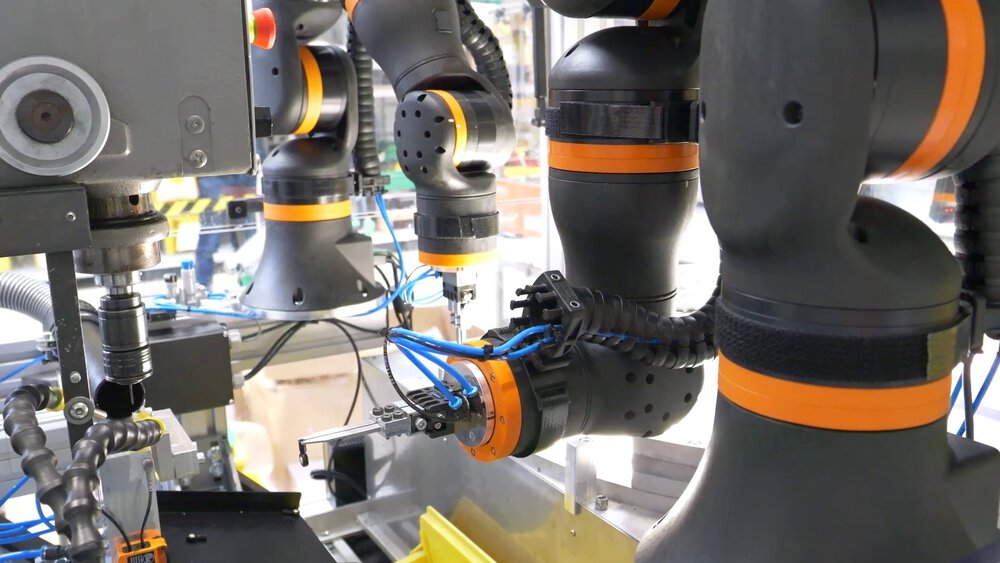

AI qualifies robots for new tasks

The easier and more intuitive collaborative robot handling gets, the more application potential is unlocked. So it is unsurprising that manufacturers do everything in their power to qualify their cobots for the widest possible range of tasks by using artificial intelligence. For example, Universal Robots has lately presented the UR AI Accelerator as a solution for developers to equip their robotics solutions with the latest AI technology.

Delta Electronics have taken a similar path. The company will use automatica as an opportunity to showcase their innovative Cognibot Kit and how it enables fitting cobots of the D Bot series with advanced cognitive capabilities such as voice control, 3D machine vision systems, Artificial Intelligence, and more. Delta significantly expands the range of these cobots’ deployment options across various manufacturing environments through improved performance. Michael Mayer-Rosa, Global Head of Intelligent Robot Systems (IRS) at Delta, comments: “The Cognibot Kit unlocks cognitive robotics for companies of all sizes. This is particularly advantageous for countries such as Germany where SMEs form a large part of the economy and are faced with labor shortages. Easy integration into existing environments was a key focus as it enables smaller companies to take advantage of the efficiency and flexibility that cost-effective solutions for automation in production, logistics, and service offer.”

Workable, simple solutions at automatica

Such workable, simple solutions are what European SMEs need—and automatica is the place to find them. And the best part is: The barriers to entry for automation will decrease even further very soon. Robot and systems manufacturers are working hard to develop voice-controlled models intended to make programming easy for just anyone. automatica will show just how far the developments in this sector have already come.

Downloads

165158

Belonging images

- PR Manager