Robots, assembly technology, machine vision, digital solutions – all at a single trade fair

In focus: key industrial automation technologies

- Assembly, handling technology

- Industrial robotics

- Service robotics

- Machine vision

- Software, cloud computing

- Clamping and gripping technology

- Drive engineering

- Sensor technology

- Control system, communication

- Safety components

- Electrical engineering

- Fluid technology

- Services and service providers

- Research and technology

This is unique: as the leading platform, automatica covered from June 24–27, 2025 the entire value chain of industrial automation. The spectrum ranged from individual components and complete systems to turnkey applications and highly qualified services - for all manufacturing sectors, of course. And increasingly also far beyond the manufacturing industry.

Assembly and handling technology

Assembling, joining, handling, bolting, gluing, testing, verifying, dosing – assembly and handling technology covers a variety of work steps. And they are changing as digitization and Industry 4.0 shape the assembly process of the future. What are the trends and how to smartly automate assembly processes?

Industrial robotics

Robotics is a key technology of smart automation – that drives the implementation of new production processes. Two examples: collaborative robots work hand in hand with human colleagues – without any safety fence between them. And: autonomous mobile robots independently find their way in production and assembly facilities. automatica is your opportunity to learn what is possible today and what is coming next.

Service robotics

They transport components in production facilities, independently pick goods from shelving racks, or take on tasks in the healthcare sector: Service robots do not just populate industrial production plants, but also homes, catering businesses, and all kinds of other important facilities.

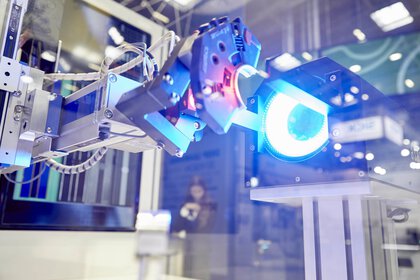

Machine vision

Machine vision systems for industrial applications have many talents. They read codes, identify components, and perform quality checks of manufactured products. And now this technology is becoming an increasingly important part of production control, too. At automatica you will experience how vision systems pave the way for digital progress in smart factories.

Software and cloud computing

Smart factories require digitization: It takes full digital mapping and control of all physical processes to make production facilities intelligent. This requires smart software – from design and production all the way to business processes and service. And: Data security should not be neglected over all the advantages of digital networking. The producers of such software will show you the current possibilities at automatica.

Clamping and gripping technology

When everything is where it should be: Grippers and clamping devices place workpieces or tools in machines and plants – with precision and flexibility. In Munich you will learn about new developments by leading suppliers and what’s next in their product pipelines.

Product categories

Grippers: electrical grippers • pneumatic grippers • hydraulic grippers • 2-finger parallel grippers • 3-finger centric grippers • suction grippers • foil gripper systems • needle grippers • adhesion grippers • revolving grippers • micro grippers • carbon grippers

Clamping devices:manual clamping devices • pneumatic clamping devices • electrical clamping devices • hydraulic clamping devices

Drive technology

This is the driving force of automation – literally. And there are several competing technologies. Apart from flexibility and service life, energy efficiency, and sustainability are becoming increasingly important factors in choosing one of them.

Product categories

bearings • linear guides • linear motion drive elements and systems • stop devices • numeric controlled rotation axes • numeric controlled linear axes • gear units • industrial motors, motor controls, motor protection devices • special drives • multi-axis systems

Sensor technology

Automated machines and production facilities require sensors to perceive their environment or recognize the processing status of products. That is why they are an integral part of any smart production environment – and seamlessly integrate into the control systems of modern production facilities. automatica showcases the entire range of sensors.

Product categories

proximity switches • rotary encoders • limit swiches • linear displacement transducers • sensors for distance and thickness • Force torque sensors • optoelectronic sensors • ultrasonic sensors / switches • identification sensor technology (RFID) • micro- sensors • pressure measurement devices • pressure switches • accessories (holders, cables)

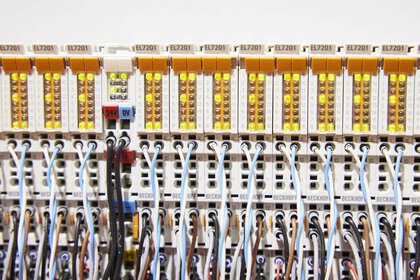

Control system technology and industrial communication

Control systems technology is the ‘brain’ and industrial communication is the ‘spinal cord’ of any automated production facility. There is plenty of untapped potential to increase productivity and flexibility here – and opportunities for implementing smart Industry 4.0 concepts. What is the functional scope of modern industrial controllers and what are the advantages of solutions based on decentralization or industrial PCs? And what’s new in communications infrastructure?

Product categories

Control technology: electronic controls • mechanical controls • pneumatic controls • CNC systems • industrial PCs • buscard

Industrical communications: bus systems, bus terminals, fieldbus components • display and operating equipment (HMI) • optical data transmission • wireless data transmission • remote maintenance and diagnostic systems • virtual reality systems for industrial applications • networking technology

Safety components

In automation technology, and in robotics in particular, the familiar safety fence is increasingly being replaced by smart safety sensor technology – or the entire safety aspect is shifted from hardware to software. Collaborative robotics require an entirely new set of safety solutions that will also be presented in Munich. Apart from safety, productivity of the affected plants is another important criterion.

Product categories

mechanical and electro-mechanical safety devices • safety-related control systems • safety-related sensor technology • safety-related components for the networked factory • safety-related drive systems • safety-related components for the networked factory • software solutions for security management and security monitoring

Electrical engineering

Every automated plant needs energy such as electricity. Having the right energy supply in the right place has an impact on the entire production process, especially if it involves moving parts and millions of cycles executed in quick succession.

Product categories

industrial enclosures, control cabinets and equipment • industrial power supply and power distribution • electrical components for controls • cable protection systems • cable and tube bushings • ventilation and cooling

Fluid technology

Another important source of energy for automated systems is fluid technology, in which energy is transferred by the flow of gases or liquids. Be it hydraulics (transfer of energy through hydraulic fluids) or pneumatics (transfer through compressed air).

Product categories

Pneumatics • hydraulics • sealing technology

Services and service providers

automatica offers a complete overview of services along the entire value chain of industrial production. Companies of all sizes are represented here – from general contractors and system integrators to highly specialized consultants. Discover a wide range of services and entirely new business models.

Product categories

general contractors • engineering, consultancy, planning • feasibility studies • simulations and industrial metaverse • CAD/CAM services • optimization of existing systems • programming • robot calibrations • trainings • condition monitoring • predictive maintenance • retrofit • mechanical, electrical and fluid technology services • certifications-, safety inspections • services for research and innovation • standardization • service providers as management-consultancies, trade associations, publishers, and many more

Research and technology

Robotics and automation are at the center of an enormous transformation process that is sweeping the industry. On the one hand, they are drivers of progress. On the other hand, advancing digitization presents major challenges to the industry. Therefore, research and new technologies are more popular than ever. At automatica, renowned universities and institutions provide insights into current research projects and thus a glimpse into the future of robotics.

Product categories

Research and development for: Industrial automation • Industrial robotics • service robotics • machine and plant construction • mobility • electrical engineering • optical technology • medical technology • environment and renewable energies • lightweight construction • battery technology

Newsletter subscription

Automation continues to progress at a rapid pace. Stay up to date: Subscribe to the free automatica newsletter.