Mobility, Flexibility, Productivity—Mobile Robots in Production

Showcase with live demo: Mesh-Up 2025

Mobile robots are revolutionizing both logistics applications and production. However, the step towards (partial) automation poses a major challenge for many companies in terms of IT architecture—especially if robots from different manufacturers are to be used in a shared fleet and on the same transport routes. A practical solution: VDA 5050. Experience the open communication interface live at Mesh-Up 2025.

More interoperability, please

With the increasing automation of production and logistics processes, IT complexity is also growing. Every mobile robot and every new solution has its own software control system that needs to be integrated into the existing IT infrastructure. In addition, users want to be able to decide individually and flexibly between different hardware manufacturers. The automotive industry was one of the first sectors to advocate the development of an open source communication interface and to participate in the development of VDA 5050. As a result, different mobile robots can now be operated in a mixed fleet with just one master controller. Mission completed.

Experience mesh-up—and implement it for yourself

How does the open communication interface between the master controller and various mobile robots work in practice? Which use cases is VDA 5050 suitable for and what needs to be considered when initiating and implementing a project? In addition to the large live demo, Mesh-Up 2025 offers direct contact with experts on site to discuss specific application options and gain a practical insight into the topic of feasibility and implementation.

Focus on production logistics

From practice for practice. The Mesh-Up 2025 focuses on the interaction between logistics and production, or more precisely: the supply and transfer of materials and the interlinking of systems and workstations. Why is the scenario shown again based on real processes? To show that the master control of heterogeneous fleets via VDA 5050 has long since arrived in practice.

Moderated live demonstrations

The showcase features a fleet of different mobile robots that perform transport and manipulation tasks in production logistics and floor cleaning. The highlight is that a single master control system orchestrates a total of ten robots from eight different vendors. This is made possible by the use of the open communication interface VDA 5050.

For users, this means flexibility in the choice of software and hardware. Different requirements can be covered with suitable robots and controlled centrally via software. This takes care of traffic and order management, so that the vehicles can also use the same routes, for example – a real game changer for automation in existing production facilities.

Where: Hall B4, Stand 330

Schedule: 13:30 / 14:30 / 15:30

Language: English

Schedule: 10:15 / 11:15 / 12:15

Language: English

Schedule: 10:15 / 11:15 / 12:15

Language: English

Time: 13:30

Language: German

Showcase details

Processes in production logistics:

- Centralized control station by MHP for the mixed fleet of robots

- Storage and retrieval of pallets using a fully automated transport robot with lifting capability by ek robotics

- Load transfer to a vehicle by KUKA that drives under the load and onward transfer to a similar vehicle by SAFELOG

- Load transport to a manual workstation: removal and simulated workpiece processing

- Workpiece onward transport to goods dispatch with a mobile robot by dpm

- Transfer of the filled small load carrier to a provisioning station by WAITKUS

- Transfer of the empty small load carrier to a mobile robot by SAFELOG using an OMRON manipulator following goods removal

- Automated transport of empties (pallet and small load carrier) to a robot cell by INOS, performed by mobile robots from KUKA and Bosch Rexroth

- Onward transport of the loaded pallet by a SAFELOG vehicle driving under the load

- Integration of a Kärcher cleaning robot into the fleet via VDA 5050

Also: Integration of the M2X research project investigating additional interface requirements for automated mobile robot deployments. It showcases direct communication between a robot by Fraunhofer IML and an active station (machine or system).

The hosted live demonstration in the event area is broadcast on large screens. Timeframe: Tuesday afternoon, Wednesday morning, Thursday morning, and Friday afternoon.

How about a little preview? Watch our Making of Mesh-Up.

Overview of participants

Insights: Mobile robots on the rise

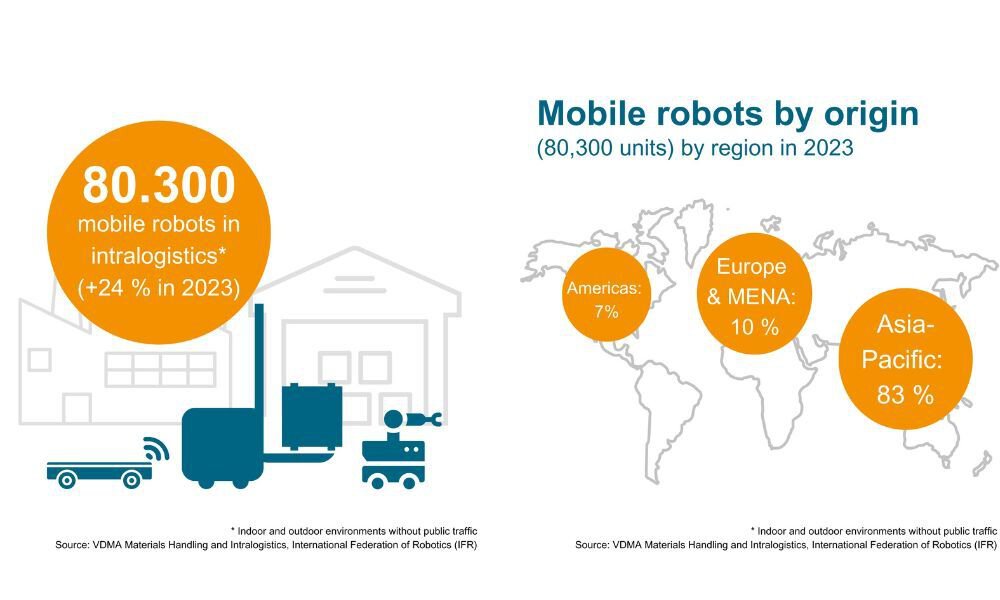

According to the annual report "World Robotics—Service Robots" by the International Federation of Robotics (IFR), almost 113,000 robots were sold for transportation and logistics tasks in 2023. Almost 80,300 of these are mobile robots that transport material indoors or outdoors, are used in production supply or warehousing and for loading and unloading trucks and pallets.

VDA 5050—the most important background information

Coordination between mobile robots is becoming increasingly important in warehouses and production. This is because the number of material transports is growing, but not the available space. The number of manufacturers and systems is also increasing, which makes it difficult to design a uniformly operating fleet. These framework conditions led to a special cooperation in 2017: between the German Association of the Automotive Industry (VDA) and the VDMA Materials Handling and Intralogistics Association.

The partners put together a project team consisting of manufacturers of mobile robots, providers of master control software and users from industry to develop an interface. The aim and result: vehicles and control systems should be able to communicate with each other regardless of the manufacturer. The first version of VDA 5050 was published in 2019 and has been continuously adapted to current market requirements ever since. The current version 2.1.0 is accessible via a public GitHub repository and can be commented on.

Date | Tuesday, June 24 until Thursday June 27, 2025 |

Time | Tuesday: 10:15; 11:15 and 12:15 every 15 min |

Place | Hall B4.330 |

Language | English |