Cobots and industrial robots conquer new fields of application

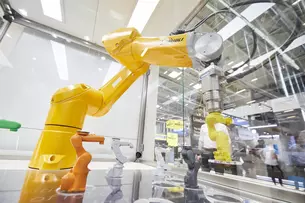

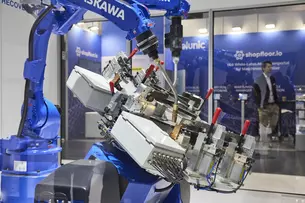

Networked digital automation solutions pave the way for efficient, resource-conserving, and sustainable production. Experience the latest six-axis robots, scaras, delta robots, cobots, and other indispensable systems for future climate-neutral production processes.

There’s no question about it: the production of many product groups would already be absolutely impossible without the use of robots. The automotive industry is a prime example: no robot = no car. It really is that simple. And the number of industries and sectors where this equation is equally applicable increases every day. Food and pharmaceutical industry, photovoltaics, electronics, medical technology, fuel cell production – these and many other highly sensitive fields of application will soon be almost inconceivable without the use of robots. And last but not least: the wide field of human-robot collaboration, which has been gaining tremendous momentum recently.

The challenge: the versatile scope of application also leads to demanding requirements specifications for the robots. Most articulated arm robots, scaras, and delta kinematics were designed for use under ‘normal’ conditions. Now they have to prove their capabilities in clean rooms, sterile environments, under water, or in extremely dry production environments.

Attend automatica to see how robot manufacturers qualify their machines for such special applications with and without integrated artificial intelligence. Be inspired by the incredible range of high-performance kinematics, some of which are presented in Munich for the first time ever.

Six-axis robots that handle unpackaged foodstuffs or dispense pharmaceuticals, articulated arm robots that advance underwater nuclear power plant dismantling operations, or hyperdry scaras designs that manufacture fuel cells in an environment with a humidity below one percent, thus helping to achieve the UN’s sustainability goals. Visiting automatica is an opportunity for you to experience high-tech automation use cases for these and other spectacular applications live on site.

Get inspired by the holistic offering including cobots for human-machine collaboration and all kinds of service robot designs.

The trade fair thus reflects the rapid development of robotics and automation use cases. The number of worldwide robot installations increased by 31 percent in 2021 – despite massive production cutbacks and supply chain disruptions caused by to the Covid 19 pandemic. According to the IFR (International Federation of Robotics), the number of new industrial robots installed around the globe in 2021 has risen to an all-time high of 517,385 units. The total number of industrial robots installed in factories worldwide also reached a new record at approx. 3.5 million units. Revenue generated by the German robotics sector rose by 13 percent to 3.5 billion euros. Interesting fact: half of all robots installed worldwide in 2021 were deployed in China.