Cobots: Eleven robots that collaborate with people

Whether the MRK robots are called cobots, lightweight robots or collaborating robots, virtually all industrial robot manufacturers have special robot types for the close human-robot collaboration (MRK) in their product range in the meantime. The load capacities of these cobots range from 500 g to 35 kg. An overview.

Lightweights

ABB: Yumi

ABBs Yumi is now also available as a single-arm version, but the double-arm version of the Yumi is particularly well known. Each of the two robot arms has seven degrees of movement levels that enable human-like mobility in the most cramped spaces. The Yumi supports a maximum load of 500 g per arm and is therefore particularly suitable for small parts assembly and the electronics industry.

Denso: Cobotta

With a weight of just 4 kg and integrated control, Denso’s Cobotta is easy to transport and ready for immediate use. The graphically designed app Cobotta World ensures easy operation, and an electric gripper as well as a camera are already integrated. Cobotta has a load capacity of 500 g and consequently targets applications such as handling and assembly of small parts.

Mid-sized class 3 to 15 kg load capacity

Franka Emika: Franka Emika Robot

The easy-to-use and sensitive Franka Emika Robot from Franka Emika supports 3 kg and has torque sensors in all seven axes. There is now an online platform dealing with the cobot where partners can offer grippers and cameras or suitable applications. Franka Emika provides its own apps for the electronics industry and for packaging.

Rethink Robotics: Sawyer

The Hahn Group wants to combine Sawyer technology of Rethink Robotics from Boston with German engineering. In addition to integrated machine vision and gripping technology, Sawyer is distinguished by its simple operation. With a load capacity of 4 kg, Sawyer primarily addresses the cutting and plastics processing industry as well as the electronics industry.

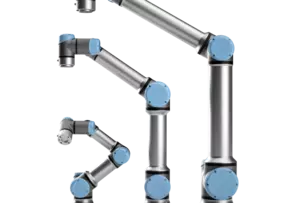

Universal Robots: UR

The lightweight arms from Universal Robots are available in three load categories: from 3 kg to 5 kg and all the way to 10 kg. A force-moment sensor on the tool flange provides more sensitivity in the new E-series. UR is especially suitable for applications relating to machine loading, packaging, assembly and surface treatment.

Bosch: Apas

Bosch's Apas automatic production assistant uses industrial robots from Fanuc (LR Mate) or Kuka (Agilus) under a specially developed protective skin. This skin is studded with capacitive sensors and stops the robot even before it comes into contact with humans. Apas is used in several Bosch plants.

Kuka: LBR iiwa

LBR iiwa from Kuka has force-moment sensors in all seven axes of motion. This also makes it fit for sensitive joining and assembly tasks. The LBR iiwa supports 7 or 14 kg. Its small brother LBR iisy has a load capacity of 3 kg and consequently is especially designed for collaborative application scenarios in the electronics industry.

Omron: TM-Cobot

Omron provides cobots from the Taiwanese Techman Robot. These are available in two series: TM5 with a payload up to 6 kg and TM12/TM14 with a payload up to 14 kg. The TM robots are easy to use and have an integrated machine vision system. Omron wants to combine TM models with its mobile LD robots in the future.

Yaskawa: HC10

Yaskawa's collaborative HC10 robot supports up to 10 kg and has force-moment sensors in each joint. The HC10 uses the same control as the Motoman industrial robots. If no one is in the vicinity, the HC10 starts at the usual industrial robot speed. There will also be a 20 kg load variant with the HC20 in the near future.

Over 15 kg

Stäubli: TX2-Touch

Stäubli's safe robots of the TX2 robot generation combine the collaboration of the cobots with the strengths of industrial robotics such as speed and precision. Robot control is the basis for safety. TX2 robots range from 2.3 to 20 kg load capacity. For demanding collaborative applications, there is the TX2 touch series with the touch-sensitive protective skin Safeskin.

Fanuc: CR Series

Fanuc uses its standard industrial robots in its CR models, which are covered with a soft green surface: A force-moment sensor in the base of the robot detects collisions. The CR series ranges from the small CR-4iA (4 kg) to the strongest model CR-35iA, which carries a hefty 35 kg. This makes CR-35iA the strongest collaborative robot to date.