The German economy is stagnating, and this is also affecting the automation industry. European robot installations are declining, but exhibitors at automatica remain confident. Now the economy is picking up!

Welcome to the automatica industry portal. Find news about digitization & AI, future of work and sustainable production

The German economy is stagnating, and this is also affecting the automation industry. European robot installations are declining, but exhibitors at automatica remain confident. Now the economy is picking up!

Volker Spanier, Chairman of the Management Board at VDMA Robotics and Head of Manufacturing Solutions, Epson Deutschland GmbH

The robotics market in pharmaceuticals, medicine, and healthcare is growing rapidly—automatica 2025 showed why this future-oriented sector is so much in focus.

With Dr.-Ing. Christopher Schneider, Business Development Manager Robotics EMEA at Yaskawa Europe Robotics Division.

Robots are becoming increasingly agile. In the shape of cobots, an ever-growing number of them joins their human colleagues to support their work.

With Mathias Behounek, CEO at SAFELOG

Proven AI solutions demonstrate their advantages in production, and with manageable investments. Exhibitors will show how this works.

With Tobias Rietzler, CEO at robominds

Upcoming technology will revolutionize all sectors of industry. Interesting how much Metaverse exhibitors at automatica will present.

With Magnus Edholm, Head of Marketing for the Digital Enterprise at Siemens Digital Industries

Robotic solutions for hygienic & cleanroom environments in great demand. Life sciences, food, laboratories, electronics, semiconductors

Peter Pühringer: Back in early nineties, Stäubli was still a niche supplier in the field of robotics. So, we focused on niche markets.

The world of robotics is changing. The humanoids are coming! And they are coming in hot.

Interview with David Reger, CEO of Neura Robotics on the topic of humanoid robots

Upcoming energy generation methods require new technology and production processes, thus generating a billion-dollar market for the automation sector.

The phase-out of fossil fuels will lead to a significant increase in global electricity consumption and, thus, to a transformation process of enormous proportions.

The question of data sovereignty is not clearly regulated by law: Interview with Uwe Seidel, Head of the Working Group “Legal Challenges” of the Federal Ministry of Economics and Energy.

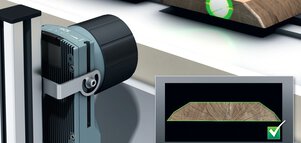

Industrial measurement will play a central role in the production of the future.

With the help of industrial analytics, companies want to gain added value from production data. Intelligent data analysis software alone is not enough.

IoT platforms connect devices and applications, machines and factories in the Internet of Things. With the large number of providers, obtaining an overview is often not very easy.

The IoT boom makes edge computing necessary, but data processing in the cloud is more dynamic and therefore scalable to any extent.

GAIA-X: The Secure European Cloud Is Taking Shape. A secure and data-sovereign European cloud infrastructure for SMEs – that is the goal of GAIA-X. That is why government, business and science are promoting the project.

Autonomous production of the future configures and coordinates its production cells itself. Industry pioneers are already implementing the characteristics of the smart factory.

Overview of the most important aspects: What is autonomous production? What is the current situation? What role do people play in this?

Five aspects of driverless transport systems (DTS) in pro-duction, which absolutely must be considered in planning

Industrial machine vision is well advanced when it comes to the use of artificial intelligence and in particular deep learning.

Artificial Intelligence in Production: With Assistance Systems for Autonomy.

German government has recognized the importance of AI and has developed an AI strategy.

Tips and tricks for an introduction to machine learning.

Will artificial intelligence (AI) someday make robots smarter than humans? This is what robotics and AI experts have to say.

How much autonomy does production tolerate? What are the opportunities and limits of artificial intelligence? A prominent survey of AI professionals.

The training sector offers numerous application possibilities for automation.

Cobots have paved the way for human-robot collaboration (HRC). Currently, the trend is toward heavy-duty HRCs in industry, while lightweight robots are still in the trial and discovery phase.

Demand for mobile transport systems is booming. The number of logistics robots sold rose by a remarkable 60 percent in 2018, the International Federation of Robotics (IFR) reported.

AI systems can be helpful assistants for factory workers. Plamen Kiradjiev and Jochen Benke from IBM explain in an interview how this can reduce machine downtime.

Whether the MRK robots are called cobots, lightweight robots or collaborating robots, virtually all industrial robot manufacturers have special robot types for the close human-robot collaboration.

Robotics and automation specialists are supporting the fight against the corona pandemic 2ith innovative approaches. Robots help to carry out corona tests.

Smart Factory: Assistance Systems for Workplace 4.0. Dr. Matthias Peissner of the Fraunhofer Institute for Industrial Engineering and Organization IAO assesses future technologies for workplace 4.0.

Crisis as an opportunity? Why production managers should rely on adaptive robots even before corona—but at the latest now.