Economic recovery on the horizon

The German economy has been stagnant for a long time now. The effects are felt in the automation sector, too. Robot installations in Europe have been declining recently. However, exhibitors at automatica 2025 continue to look forward with confidence. As it turns out, they are right to do so: The economy is finally picking up again.

- Positive indicators for robotics and automation

- Mercosur free trade agreement strengthens the export economy

- Automotive industry regains momentum

- Double-digit growth in mobile robots

Even though real gross domestic product (GDP) growth in 2026 is expected to remain at a moderate level of 1.7 percent according to a forecast by the German Institute for Economic Research (DIW), the trend now appears to have reversed after years of stagnation. With an unexpected GDP growth of 0.6 percent currently predicted for the fourth quarter of 2025, the current Nowcast forecast model indicates that the economy has already picked up.

And this economic forecast does not even take the effects of the Mercosur agreement into account. The free trade agreement between the EU and the South American economic organization Mercosur, which covers Argentina, Brazil, Paraguay, and Uruguay, was signed in January with the goal of deepening trade relations by reducing customs duties. According to estimates, the agreement could increase EU exports to South America by up to 39 percent. This would be equivalent to an increase in the total European economic output of approximately 50 billion euros.

Automotive industry slowly picking up speed again

In addition to the mechanical engineering and pharmaceutical industries, the ailing automotive industry is expected to greatly benefit from the free trade zone as its exports had previously been subject to tariffs of 35 percent. This positive outlook could further boost sentiment in the automotive industry.

According to an ifo economic survey, the industry’s business climate index started improving back in December 2025: Companies are now less pessimistic about their economic situation in coming months. “Developments in the electromobility sector are a ray of hope. Almost 55,000 new battery-powered electric vehicles were registered in Germany in December 2025. That is more than 22 percent of all newly registered cars. Electric mobility seems to have arrived in Germany” says ifo industry expert Anita Wölfl.

Robotics and automation: positive indicators for 2026

The revival of the automotive industry, the impact of economic stimulus packages, investments in defense, the boom in e-commerce, AI initiatives, and the unresolved lack of specialists are some of many factors indicating a return to the growth path envisioned for the European automation industry—just as predicted by exhibitors at automatica 2025.

Thus, the downward trend observed in 2024, when the IFR (International Federation of Robotics) reported a decline in robot installations by eight percent in Europe and five percent in Germany, which was followed by a further installation decline in 2025, should be a thing of the past now.

Stable growth in mobile robots

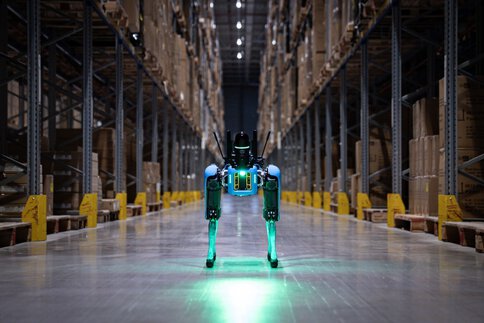

Meanwhile, mobile robot systems are excellent business. The IFR reported global sales of approx. 102,900 mobile robots for transport and logistics tasks in 2024. This is an increase of approx. 14 percent over to the previous year.

There are multiple reasons for the growing popularity of these mobile solutions, particularly in intralogistics applications. One of them certainly is strong growth in the e-commerce sector. The breakthrough in artificial intelligence and innovative navigation technologies lends even more momentum to this trend. Such technologies enable mobile robots to plan their routes autonomously and avoid obstacles. automatica 2025 already saw some demonstrations of just how much AI facilitates robot integration. And that makes the whole thing attractive for smaller companies with little experience in robotics.

Other reasons for the upswing in the market include steady growth of mobile robot portfolios, a severe lack of specialists, and the cost-effectiveness and scalability of these highly productive solutions. Sascha Schmel, Managing Director of VDMA Materials Handling and Intralogistics, shares this view. “We are seeing great demand for automation solutions involving mobile robotics. However, such projects often involve considerable investment and effort on the part of the customer. Simplifying the framework conditions for commissioning and deployment remains a key task for both suppliers and customers.”

Artificial intelligence revolutionizes intralogistics

A multi-million dollar project by Otto Group, the largest online retailer of European origin with more than 36,000 employees, is an impressive example of how smart robotics can revolutionize intralogistics processes. Otto, in cooperation with NVIDIA and their service partner Reply, is developing a “Robotic Coordination Layer”. It serves as an interface between robot fleets in physical warehouses and digital twins—exact virtual representations of the logistics centers involved.

The digital twin visualizes the positions and movements of all robots in real-time, thus enabling seamless interactive process control and management. This enables the Otto Group to simulate, train, and commission various robot types—such as autonomous mobile or stationary robots—much faster. NVIDIA’s AI infrastructure provides the foundation for this digitization effort.

“We started using AI and robotics in logistics more than three years ago. Our experience so far underlines the huge potential in terms of greater efficiency and better service” explains Kay Schiebur, Member of the Executive Board, Services at Otto Group. “And now we are taking smart automation to the next level in cooperation with NVIDIA and Reply. This partnership lets us create the basic infrastructure required for our innovative robot networking. It puts us in a position to quickly scale robotics solutions as part of complex intralogistics processes and to strengthen our position as a leading responsible company with a focus on Europe.”

Latest emerging trend: robotics-as-a-service

Such lighthouse projects involve considerable investment and effort while many SMEs even lack the means to implement much more modest intralogistics projects. This is where RaaS comes in. RaaS stands for robotics-as-a-service. It is a flexible subscription model for robots that avoids large initial investments and long-term capital commitment, thus enabling small and medium-sized enterprises in particular to implement advanced automation. RaaS is also a great option for companies looking to evaluate the benefits of robotics through trial operations in their own environment before making a permanent commitment.

Its scalability is another advantage of this solution. For example, the number of deployed robots can be adapted to current demand. This flexibility is particularly valuable for seasonal businesses or companies requiring quick reactions to changing market conditions. So it doesn’t come as a surprise that the popularity of RaaS offerings is growing rapidly as it saw a 42 percent increase in 2024 over to the previous year.

This is a promising market in the making and it will be interesting to see what products manufacturers will come up with next. By the time automatica 2027 comes around, robotics-as-a-service will surely be much more established.

Ralf Högel on behalf of Messe München