Many more metal men: ambitious goals for humanoid mass production

May 15, 2025

- Manufacturers exhibit the current state of development at automatica 2025

- High growth expectations among tech giants and politicians

- Igus and Neura Robotics present innovative approaches from Germany

Humanoid robot development is progressing at an impressive pace. The power struggle between the US and China, along with advances in AI, battery development, and mechanics, has led performance improvements among the metal men. automatica will show how far this development has progressed by now.

The humanoids from China recently had an opportunity to show their capabilities during a half marathon in Beijing. Around 20 humanoid robots successfully competed against humans during the 21-kilometer run. With this race, the People's Republic achieved its goal of presenting the country as a leading supplier of human-like robots.

Two legs unlock maximum flexibility and mobility

A half marathon raises a frequently asked question once again: Why do humanoids have legs? Wouldn’t wheel drives be more efficient? Jonathan Hurst, Chief Robot Officer at Agility Robotics, explains why most humanoids still have two legs: “Two-legged robots are designed to coexist with humans and offer great versatility and mobility beyond the possibilities of wheel drives. With their legs, humanoids can adapt to complex environments, walk up stairs and curbs, and perform a wide range of tasks.” Digit, Agility's humanoid robot, is already being used in a number of applications—primarily in logistics centers operated by companies such as amazon and GXO Logistics. With a height of 1.75 m and an approximate weight of 64 kg, Digit can take on complex tasks such as lifting loads weighing up to 16 kg. And advanced sensor technology based on LIDAR and cameras even enable it to navigate independently. Melonee Wise, Chief Product Officer at Agility Robotics, will also discuss Digit and how humanoids can fill gaps in the automation chain during her presentation at automatica Forum in Hall A5. She will be followed by Carolin Richter, Head of Next Generation Robotics at BMW Group, who will deliver an application-centric speech on her company’s experience with specific humanoid deployments in practice.

The US and their pioneering role in tech development

Just like Digit, other sophisticated humanoids are from the US as well. They include Atlas by Boston Dynamics, Optimus by Tesla, Figure 01 and 02 by Figure AI, and Apollo by Apptronik. All of them already work in the automotive industry as part of pilot projects. Jeff Cardenas, CEO and co-founder of Apptronik, comments: “We are developing the world's most advanced and performant humanoid robots to assist humans in sensible and revolutionary ways.” However, driving these developments takes a lot of capital investment and strong supporters. Apptronik just raised more than 350 million USD in its latest round of financing. Cooperations with NASA, NVIDIA, and Google DeepMind as well as users such as Mercedes-Benz and GXO Logistics are intended to maintain Apptronik’s leading role in this promising market.

Germany lags in humanoid robotics

Even though Germany does not currently play a key role in the global humanoid market, automatica provides proof that the country still offers promising developments. Apart from the 4NE-1 by Neura Robotics, first introduced at automatica 2023, additional humanoids will be exhibited in Munich this year. One of them is ‘Iggy Rob’ from Cologne. Igus offers their first humanoid robot for just under 50,000 Euros. According to the manufacturer, this has been achieved by combining proprietary components such as robot arms from the ReBeL cobots und the ReBeL Move mobile platform. Its range of applications extends from assistance robotics and factory automation all the way to education and research. Igus also intends to deploy Iggy Rob for automating injection molding machines in their own premises.

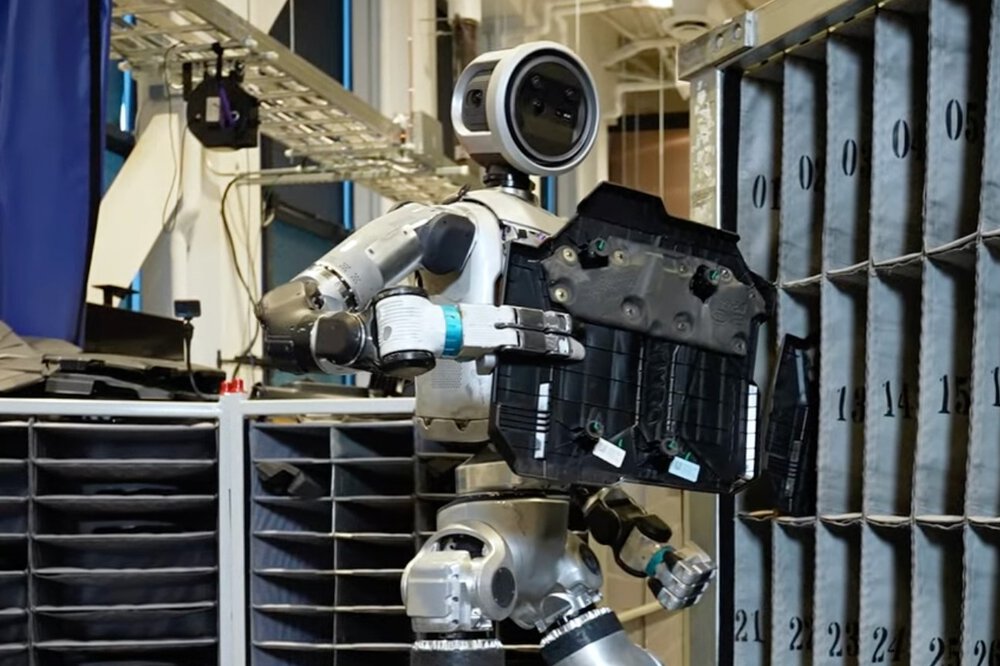

The presentation by the Institute for Robotics and Mechatronics, part of the German Aerospace Center, is another eagerly anticipated highlight. They conduct extensive research with the goal of advancing humanoid robotics. And their latest results will be exhibited at automatica. In this context, the institute’s recently announced cooperation with Siemens has caused a bit of a stir. Institute Director Alin Albu-Schäffer comments: “This strategic partnership is yet another example of the robotics-related technology transfer from aerospace to industrial applications. Given the rapid developments in the US and China, extensive networking with leading German industrial partners such as Siemens is essential to ensure the future competitiveness of European robotics.”

Humanoid robots: a huge growth market

Tesla considers itself a technology leader with their humanoid Optimus robot. It moves elegantly at great speed and features a five-fingered hand of great dexterity. Elon Musk believes that they will soon be suitable for housework or childcare, and Goldman Sachs also sees great potential in the global humanoid market. They expect a market valuation of 38 billion USD by 2035. Apart from US companies, the People’s Republic is pursuing ambitious goals as well. The country intends to become the global market leader in the field of humanoid robots within three years. In the medium term, five percent of all jobs in China are scheduled to be taken over by humanoids. This is equivalent to the deployment of around 35 million units. Chinese companies across various applications and industries already deploy humanoids by Unitree, AgiBot, Engine AI, Fourier, and Ubtech.

Industry leader Unitree is one of the world’s first to place a small humanoid on the market at a spectacularly low price—the G1. The basic version of the G1, standing 1.3 meters tall and weighing just 35 kg, will cost only 16.000 Euros in China. In Europe, however, the price is expected to be closer to 30.000 Euros. And this price can easily more than double depending on the robot’s configuration. The G1 has raised great interest, as Unitree Marketing Manager Qian Yuqi tells us: “We already have orders from China and abroad. Initially, our robot will probably be most popular among scientific research institutions, but we also know of industrial companies considering the G1 for simple tasks.”

This shows: The time of humanoids has come and, thus, a new era of automation has begun. AI already empowers them to take on some tasks that could only be handled by humans thus far. automatica promises exciting insights into the current capabilities of humanoids and their potential impact on work environments.

Downloads

168831

- PR Manager